Engineering based solutions...

Our news

Artı Otomasyon Team is composed of experienced engineers and technicians that create industrial automation solutions since 1987 until now for cement, iron and steel, chemistry, petro-chemistry, food, water treatment, energy and other sectors.

Our company recognizes the sales, project designing, engineering, commissioning and after sales services for PLC and higher systems such DCS systems, performs PCS7 Process Control Systems and Process Instrumentation as a partner of Siemens Solution.

As SIEMENS Solution Partner, we will be glad to share with you our experience and knowledge we have acquired for many years.

“Hoping to serve you, incorporate a plus to your business and the development of our country”.

Firsts from ARTI

Artı Otomasyon Team is composed of experienced engineers and technicians that create industrial automation solutions since 1987 until now for cement, iron and steel, chemistry, petro-chemistry, food, water treatment, energy and other sectors.

By realizing importation of Texas Instruments PLC Devices through Turkey General Distributorship with a different organization, we put across turnkey automation applications by performing the project designing, software and after sales services.

As from 1992 in consequence of the purchase of the PLC part of Texas Instruments of SIEMENS, we still continue to render services concerning these products that have changed as SIMATIC TI.

While carrying on his works relating to engineering works as well as equipment procurement and software support relating to SIMATIC TI, SIMATIC S5, SIMATIC S7, SIMATIC PCS3 and SIMATIC PCS7 Systems, ARTI Automation, as SIEMENS Solution Partner, renders at the best spare-part and maintenance services by acting in accordance with the after-sales service awareness.

•

Engrain in immovable confidence feeling to customers.

•

Act in accordance with the needs of customers along the project process.

•

Meet in the fastest way the technical service and spare-part needs of customers within the continuity awareness in industrial production and after-commissioning.

•

Offer, as the best business partner, the most profitable products and services to his customers and ensure continuous customer satisfaction.

•

Keep to professional understanding principle by working in planned and disciplined manner.

The heavy competition conditions encountered in production branches of any business are subject of discussion. At this point manufacturing only is not so important. However the production will gain meaning only if realized in fast, standard, reliable and perfect manner also gain competitive facts in this case. Just at this point "automation" becomes a part of the business.

Automation is remarkably important in industry as it is the source of increasing the production and maximizing the productivity. As automation is installed and improved, the industrial production will continue to improve in direct proportion with it. It is not possible that industry without automation may be successful and competitive.

That is exactly for that reason that ARTI Otomasyon is here to keep alive the competitive powers of his customers by adapting them with advancing technological improvements.

We design and realize your projects by meeting your expectations with systems at optimum cost, maximum quality and reliability by determining the necessary equipment, software, hardware,, production and mounting facts.

Our projects are realized with a coordinate work of the teams indicated hereunder under the supervision of a project officer engineer.

Electrical design,project team;

It is composed of engineers and technicians that undertake the tasks of designing, planning and manufacturing of power distribution, MCC and PLC boards conformed to project requirements.

Automation hardware, software team;

It is composed of engineers responsible of the PLC and HMI software preparations in accordance with the system functioning scenario by determining the hardware architecture ensuring the system requirements and determining the necessary software packages.

In addition to PLC and HMI software established by experienced software engineers it is also possible to prepare reporting software according to customers’ requirements such as production, consumption, failure, equipment monitoring that is special to various sectors.

Hence you will have the opportunity to monitor closer and in detail your process, preserve these data for a longer time and retroactive poll. You can also share the data obtained in context such as Excel, SQL.

Our company recognizes the sales and after-sales support services relating to hardware and software matters of product groups of Siemens S7-300, S7-400, PCS7, HMI (Scada systems, Operator panels).

You can contact us by e-mail satis@artiotomasyon.com or by phone at the number 0212 216 47 33 for any demand concerning the sales.

Our company has determined his priorities in order to ensure his customers the quickest and more efficient manner after-sales and commissioning support services.

Our technical team is ready to serve our customers concerning casual systems such as Simatic S7 and Simatic PCS7 Systems as well as Simatic TI serials.

In case you need our technical support, you can contact us by e-mail destek@artiotomasyon.com or by phone at 0212 216 47 33.

Our company aims at ensuring your technical staff responsible of the maintenance and repair to know the automation system they use well, to solve quickly the troubles in place by giving them trainings concerning failure intervention, maintenance, revision and trouble shooting.

In accordance with this purpose, our company, if you please, can give hardware and software trainings whether in your company or at our training office concerning the following product groups.

Simatic S7-300

Simatic S7-400

Simatic PCS7

Simatic WinCC and WinCC Flexible

If you also want your team to get the better of your system, have les troubles and quicker solutions then contact us.

Engineering Based Solutions

Process Control Systems- SIMATIC PCS7

SIMATIC PCS 7 which is away from traditional IDCS systems offers at the same time the unique scalable architecture with strong engineering means and integrates the alarm management, process security and asset management.

SIMATIC PCS7: carry you far from the limits. It offers a perfect t INTEGRATION platform for all kinds of industrial standards going from Industrial Ethernet to Profibus, from OPC to HART. High speed and powered CPU with 8 ns bit process time has a unique PERFORMANCE with its Gigabit Ethernet infrastructure and flexible modular redundancy concept at any level. It is a SCALABLE DCS system extendable to 12 redundant servers and 32 clients from 100 I/O system to 120.000 I/O system. It offers modern, reliable and trouble-free MODERNISATION solutions for either Siemens systems or 3rd party systems. For the FACILITY and DATA SECURITY, it hosts industrial software and hardware that are part of DCS system. Its integrated Fail Safe structure gives an INNOVATIVE DCS system through its components such as Simatic Batch, Simatic Route Control and Asset Management.

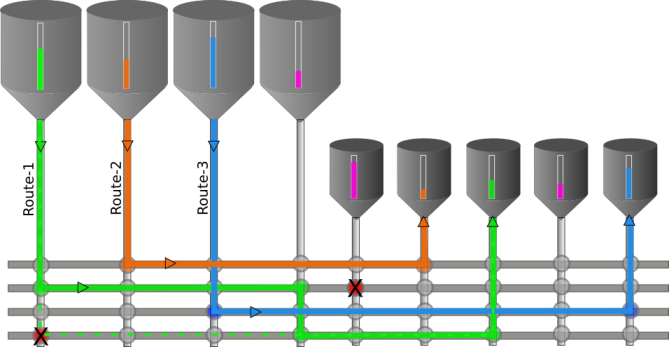

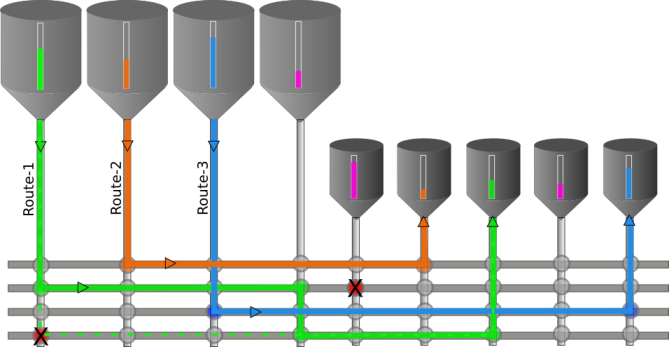

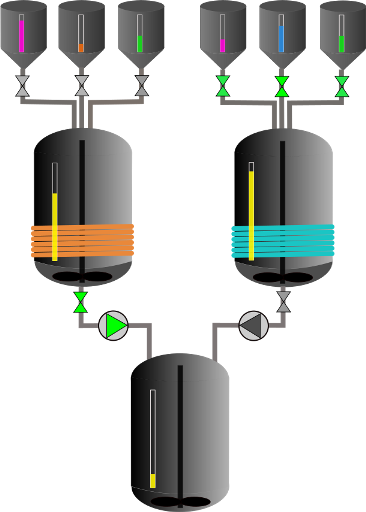

Route Control is an application giving you great convenience relating to configuration, control, monitoring and diagnostic for product transfers done with complicated pipelines in your facility.

It offers you in tank farms used widely in food, chemistry, petro-chemistry and industries alternative, complex transfer ways. Route Control is not appropriate for standalone use. It is only used as add-on in Simatic PCS7 application but when used with Simatic Batch application it is software providing really great convenience to your facility.

It can determine very quickly the probable ways by calculating all probable matrix in a system installed with valve islands and realizes more than one transfer at the same time. As it follows itself the way under use as well as the ways to be used it annihilates the troubles of the mistaken mixture of products. You can easily realize the changes in your valve and pipe lines that you will add or remove from your process.

It allows discrete manufacturing process in process industries such as pharmaceutical, food and chemistry and is named “BATCH”, it becomes the most important structure of the manufacturing process of companies involved in this industry.

The consumers want the products they use to be QUALITY and ECONOMIC and make their choices according to these criteria. That is for this reason that the producing companies are forced to realize their production for each “BATCH” with the same quality, conformed to the limits determined by the economic laws as well as standards, they should also be conform to the quickly changing requirements of the market. Establishing a process that should be extremely flexible and optimized in order to meet all of these requirements can only be possible with advanced automation. At this point SIEMENS proposes a system that can meet the requirements of such automation level: “SIMATIC BATCH”

SIMATIC BATCH is a part of the system SIMATIC PCS7 of SIEMENS which is leader in their own market and which was designed for process industry.

The following functions are offered as standards with SIMATIC BATCH.

-Creation of FORMULA as easy and simple graphic use

-Control (such as start-stop-hold-abort) and monitoring of the FORMULA while using the graphic during the formula creation

-SERVER-CLIENT structure that allows works with more than one controller at the same time

-Formation of authorization level and access constraint of data

-Record and report of events during BATCH

-Production planning and data transfer to advanced PPS systems

-Modular extendibility and flexibility

-Conformed to prosperous applications and ISA SP88 standards

|

Simatic PCS7 Sistemi

Simatic PCS7 Sistemi

Simatic S5 Series

Simatic S5 Series

Simatic S5 Series

Simatic S5 Series

Simatic S7-300 Series

Simatic S7-300 Series |

Cement Mill-1 Automation

Cement Mill-4 Automation

Cement Mill Automation

Cement Mill Automation

Cement Mill Automation

Cement Packaging Automation

Ash Plant Automation

Kiln and Cooler Sys. Automation

|

|

Simatic TI Series |

Cement Packaging Automation |

|

Simatic TI Series |

Cement Mill Automation |

|

Simatic S7 S-200 Series

Simatic S7 S-300 Series |

Concrete Plant Automation

Dust Collecting System Automation |

|

AB SLC505 Series |

Kiln and Feeding Automation |

|

Simatic S7 S-300 Series |

Dust Collecting System Automation |

Cement Industry References

Iron-Steel Industry References

|

Simatic PCS7 System

Simatic PCS7 System |

7th Lime Plant Dust Collector System Automation

8th Lime Plant Dust Collector System Automation |

|

AB SLC500 Series

AB SLC500 Series

AB SLC500 Series |

Compressor System Automation

9th and 10th Drinking Water System Automation

11th and 12th Drinking Water System Automation |

|

Simatic S7-400 Series |

Dust Collecting System Automation |

|

Simatic S7-300 Series |

Compressor Automation |

Chemistry Industry References

|

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series |

Na2 S2 O5 Production Plant Automation

Acid and Caustic Washing System Automation

Teksiar Project Automation

Teksiar Project Phase 2 Automation

Demineralized Water Plant Automation |

|

Simatic TI Series

Simatic TI Series |

Mixing Plant Automation

Autoclave Plant Automation |

|

Simatic TI Series |

Argon Drying Automation |

|

Simatic TI Series |

Drying System Automation |

|

Simatic TI Series

Simatic TI Series |

Enameled Wire Plant Automation

Shrink Packing Machine Automation |

|

Simatic S5 Series |

Conveyor Automation |

|

AB SLC500 Series

Instrumentation & Simatic S7-200 Series |

Dust Collector Plant Automation

Tank Farm and Reactor Automation |

|

AB SLC500 Series |

Borax Dissolving Plant Automation |

|

Simatic S5 Series |

Sludge Burning Plant Automation |

|

Simatic S7-300 Series |

Oil Production Recipe Automation |

|

Simatic UMG503 Series & InTouch Scada

AB Control Logix Series |

Energy Monitoring Automation

Detergent Production Plant Automation |

|

Simatic PCS7 Series + Batch Control System + Redundant Fail-Safe System |

Polymer Production Plant Automation |

|

Simatic PCS7 Series |

Rosin Production Plant Automation |

|

Simatic PCS7 Series |

Raw Oil Preparation Plant Automation |

Food & Beverage Industry References

|

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series |

Corn Oil Drying Plant Automation

Carbon Plant Automation

Starch Drying Plant Automation

Corn Drying Plant Automation

Syrup Discharge Plant Automation

Glucose Treatment Plant Automation

Glucose Treatment Plant Automation-II

Bran Drying Plant Automation

Bran Drying Plant Automation Rusya |

|

Simatic TI Series |

Press Automation |

|

Simatic TI Series |

Chocolate Preparation Plant Automation |

|

Simatic TI Series

Simatic PCS7 System

Simatic PCS7 System + Simatic BATCH Control + Simatic ROUTE Control |

Margarine Packing Machine Automation

Mixing Plant Automation

Margarine Preparation System Automation

|

|

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic TI Series

Simatic PCS3 System

Simatic PCS3 System |

Hydrogen Plant Automation

Oil Mixing Plant Automation

Winterisation Plant Automation

Sugar Dissolving Plant Automation

Hardening System Automation

Calve Production Line Automation

Margarine Production Line Automation

Schroder Professional Oil Production Plant Automation

Ines Project Automation

Tank Routing Automation |

|

Simatic PCS7 System

Simatic PCS7 System |

Bleaching - Winterization - Deodorization System Automation

Prepress - Dehulling System Automation |

|

Simatic PCS7 System |

Biodiesel Plant Automation |

|

Simatic PCS7 System

Simatic PCS7 System |

Water Distribution System Automation

Phase 1

Water Distribution System Automation

Phase 2 |

|

Simatic S7-300 Series

Simatic S7-300 Series

Simatic S7-300 Series

Simatic PCS7 System

Simatic PCS7 System

Simatic S7-300 Series

Simatic PCS7 System

|

Extraction Plant Automation

Artı Gıda A.Ş.

Extraction Plant Automation

Erdiller Yağ

Extraction Plant Automation

Diyarbakır

Prepres ve Extraction Plant Automation

Noble - Güney Afrika

Prepres ve Extraction Plant Automation

Aves Yağ - Mersin

Prepres ve Extraction Plant Automation

Seçer Tarım - Mersin

Prepres ve Extraction Plant Automation

Beta Ziraat - Konya |

Automotive Industry References

|

Simatic TI Series |

Rubber Baking Machine Automation |

|

Simatic TI System |

Exhaust Pipe Production Plant Automation |

|

Simatic TI Series |

Rubber Baking Machine Automation |

|

Simatic S7-200 Series |

Cutting Machine Automation |

|

AB PLC5 Series

AB Control Logix Series

AB Control Logix Series (Redundancy)

AB Compact Logix Series

AB PLC5 Series |

Carbon Black Loading System Automation

Extruder Line Automation

Nitrogen Distribution System Automation

Compressor Automation

Carbon Black Loading System Automation Phase 2 |

Treatment Industry References

|

Simatic PCS7 Redundant

Simatic TI Series |

Demineralized Water Plant Automation

Treatment Plant Automation |

|

Simatic S7-200 Series |

Water Softening Plant Automation |

|

Simatic TI Series |

Waste Water Treatment Plant Automation |

|

Simatic TI Series |

Waste Water Treatment Plant Automation |

|

Simatic TI Series |

Water Softening Plant Automation |

|

Simatic TI Series |

Demineralized Water Plant Automation |

|

Simatic TI Series

|

Demineralized Water Plant Automation

Seka Çaycuma |

|

Simatic TI Series |

Treatment Plant Automation |

|

Simatic TI Series

|

Treatment Plant Automation

Türkmen Holding |

|

Simatic TI Series |

Treatment Plant Automation |

|

AB SLC500 Series |

Treatment Plant Automation |

|

Simatic TI Series

Simatic S7-300 Series

Simatic S7-300 Series |

Treatment Plant Automation

Biological Treatment Plant Automation

Process Water Treatment Plant Automation |

|

Simatic S7-200 Series |

Water Softening Unit Automation |

|

Simatic TI Series |

Water Softening and Demineralized Plant Automation |

|

Simatic S5 Series |

Demineralized Water Plant Automation |

|

Simatic TI Series |

Treatment Plant Automation |

|

AB SLC500 Series |

Treatment Plant Automation |

|

AB SLC500 Series |

Treatment Plant Automation |

|

Simatic S7-300 Series |

Demineralized Water Plant Automation |

|

Simatic S7-300 Series |

Demineralized Water Plant Automation |

|

Simatic S7-300 Series

Simatic S7-300 Series |

Demineralized Water Plant Automation

Demineralized Water Plant Automation |

|

Simatic S7-300 Series |

Demineralized Water Plant Automation |

|

Simatic S7-300 Series |

Treatment Plant Automation |

|

Simatic S7-300 Series |

Treatment Plant Automation |

|

Simatic S7-300 Series

Simatic S7-300 Series |

Sludge Dewatering Plant Automation

Sludge Dewatering Plant Automation |

|

Simatic S7-300 Series |

Demineralized Water Plant Automation |

|

Simatic S7-300 Series

|

Waste Water Treatment Plant Automation

Menemen Belediyesi |

Thanks to its own reporting system, Route Control can see the retroactive productions and send them to CSV format.

As Simatic Route Control is integrated with PCS7 too it allows control and monitoring from the same operator station.

Artı Otomasyon applications;

Place: Marsa Gıda

Implementation: Mixing Unit

Realization of transfers of raw materials found in tank farm to preparation tanks in different ways.

QUESTION: Do you need to use SIMATIC BATCH?

If;

-You realize discrete production

-The previous package quality is not the same with the following package quality

-You cannot realize modifications on the working formula

-You don’t know at which step is the working formula

-You cannot hold, abort or restart the working formula

-You cannot work with several formulas at the same time

-You cannot record the steps of a working formula, cannot answer to questions such as when did it start, when did it finish, how long does it take

-Your formula doesn’t start automatically at the hour and minute planned according to the weekly, even monthly production plan

-You cannot give a label to your production (BATCH ID) and cannot report the BATCH results related to this label, cannot transfer data to advanced information systems (such as ERP,MIS)

-You don’t know the steps of a product manufactured in the past (for ex; on 15th of March two years ago at 17:00; the heating step of the formula coded 123456XMKL applied to the reactor numbered 2 was delayed for ten minutes, because the heating valve couldn’t be opened entirely for pneumatic trouble)

-The software of the control system you use is not conformed to ISA SP88 standards, you know or not that your production is not conformed to consumer standards of developed countries of the world

YOUR ANSWER SHOULD BE YES

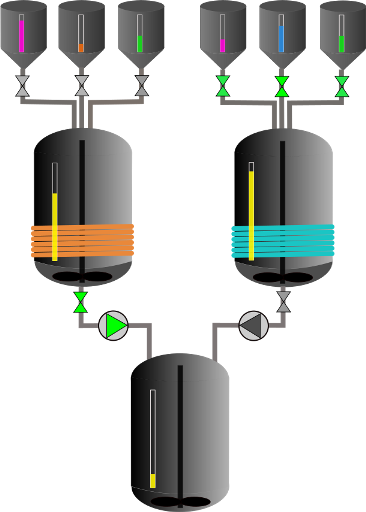

ARTI Otomasyon Applications;

Place: Marsa Food Company

Implementation: Mixing Unit

Mixing of various raw materials found in various tanks with reactors through formulas and make prepared them in order to obtain Margarinee.

Place: Kemiteks Chemistry

Implementation: Polymer Facility

Mixing of chemical raw materials found in different tanks at defined various proportion, put them in chemical reaction, ensure the completion of the reaction in a controlled manner and hence realize the production of polymer.

Barbaros Bulvarı Barbaros Apt. No:74/14

Balmumcu Beşiktaş İSTANBUL

+90 212 216 47 33

+90 212 273 00 83

bilgi@artiotomasyon.com

ARTI ENDÜSTRİYEL OTOMASYON SİSTEMLERİ TİC. LTD. ŞTİ.